Over the last few years, more and more businesses have chosen to invest in fiber lasers. Primarily adopted by the automotive industry, fiber lasers are now being used in a wide variety of industries across a wide range of applications.

Here are five advantages to consider when choosing a fiber laser.

1. Extra Speed

Speed and throughput are critical in any production. The sheer speed of

While older, more established laser technology is available—including diode-pumped solid-state (DPSS) lasers and lamp-pumped lasers – none can beat a fiber laser for combined mark speed, quality and most definitely, reliability!

2. Lower Running Costs

Fiber lasers provide cost savings long-term from ultra-low power consumption and consumables. Despite being faster, fiber lasers are energy-efficient compared to the alternatives. Not only does this result in reduced power consumption, but it also helps make the system simpler, more compact, and more reliable.

3. Space Saving

Fiber laser technology runs very efficiently. Lower power wattages require basic air cooling only, rather than an additional chiller unit. With many businesses finding floor space in short supply, compact and efficient fiber laser marking solutions are proving to be the right fit.

4. Longer Life

The life expectancy of a fiber laser far exceeds that of other laser-based technologies. In fact, the diode module in a fiber laser typically lasts three times longer than other similar technologies. Most lasers have a life of around 30,000 hours. Fiber lasers have an expected life of around 100,000 hours.

5. Easy to Use

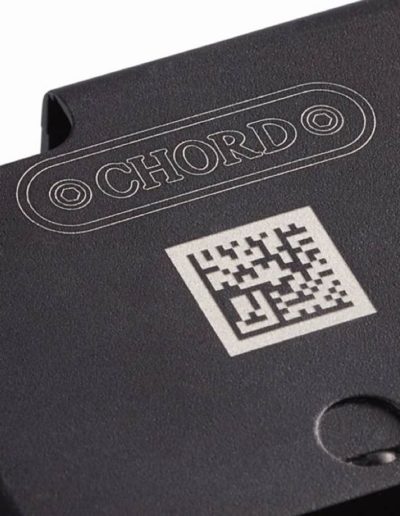

Our range of fiber laser machines

Materials

Our fiber laser systems can etch and mark a wide variety of plastics and metals. Below is only a sample of some of the materials that have been marked with one of our fiber laser systems.

- 17-4 PH stainless steel

- 303 stainless

- 4043 steel

- 6061 Aluminum

- ABS (white/black)

- Aluminum, 6061

- Aluminum, yellow chromate

- Bayer 2807 Makrolon polycarbonate

- Bayers

bayblend FR110 - Black/white ABS

- Black/white polycarbonate

- Brass

- Brushed aluminum

- Carbon fiber

- Carbon nanotube

- Ceramics, metal-plated

- Clear coat anodized aluminum

- Cobalt chrome steel

- Colored

delrin (black/brown) - Compacted powder iron with phosphate coating

- Copper

- DAP – Diallyl Phthalate

- Delrin, colored (black/brown)

- GE Plastics polycarbonate resin 121-R

Glass filled PEEKGlass filled Teflon- Hard coat anodized aluminum

- Inconel metals (various)

- Machine tool steel

- Magnesium

- Metal-plated ceramics

- Molybdenum

- Nickel plated 1215 mild steel

Nickel plated brass- Nickel plated gold

- Nickel plated Kovar

Nickel plated steel- Nylon

- PEEK, white

- Polybutylene Terephthalate

- Polycarbonate (black/white)

- Polycarbonate resin 121-R, GE Plastics

- Polycarbonate, Bayer 2807 Makrolon

- Polysulphone

- Rynite PET

- Santoprene

- Silicon carbide

- Silicon steel

- Silicone wafers

- Stainless steel 303

- Stainless steel 17-4 PH

- Steel 4043

- Steel, machine tool

- Various

inconel metals (nickel-chromiumsuper alloys ) - White PEEK

- Yellow chromate aluminum

- Zinc plated mild steel

- And Many More!