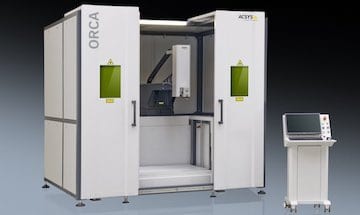

ACSYS Orca

The ACSYS power system provides maximum flexibility in terms of size and weight for an extremely wide range of workpieces. The hydraulic lift table option and flexible working area make it possible to load large heavy workpieces and mark and/or engrave them wherever necessary.

Palletised workpieces can be processed automatically. With 3 NC controlled linear axes, the ORCA® offers a machining surface of at least 1120 x 820 mm², thus providing maximum flexibility even for fully automatic operation. Powerful high-tech laser sources with high-speed

IDEAL APPLICATIONS

- Laser marking and engraving, on surface or circumference

- Intelligent segmentation with no discernible blending

- 3D engraving and micro-engraving

- Deep engraving

- Textures

- Embossing stamps

- Pressure rollers

- Printing plates

- Sinking electrodes

- Welding and cutting applications

GET THE ACSYS Orca Brochure

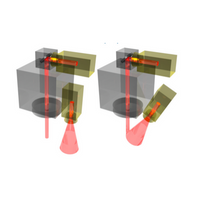

Live Adjust System®

ACSYS offers a two-camera solution for maximum precision in machining tasks. The first camera shows the entire working area. The second camera is pointed straight through the laser beam path and allows a partial high-resolution view of the workpiece that is to be machined.

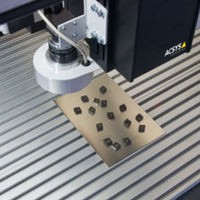

Optical Part Recognition

The optical part recognition enables the fully automated processing of non-palletized loose parts. In the example on the left, the high-resolution camera automatically recognizes the arrangement and rotational angle of the coin minting stamps.

Online Depth Control

For depth engraving and 3D engraving, the material is removed down to μm-level, ensuring high-precision results. The ODC module measures the actual engraving depth contact-free and controls the exact target depth of the laser.

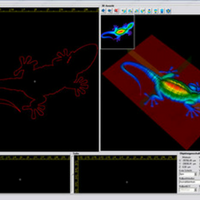

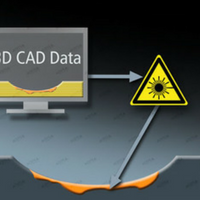

3D Assistant software module

The 3D Assistant allows a comfortable design of complex 3D engravings and micro engravings. A graphical preview simplifies the setup of the workpiece. Due to the automated readjustment of the laser focus, very deep, premium quality 3D engravings can be realized.

Dynamic Focus Control

Allows the modification of the focal point during the laser machining process. As a result, free-form surfaces can be processed without optical distortion or compromising quality. The time-consuming segmentation of the layout into different focus layers is no longer required.

Automatic Scanner Calibration

The automatic calibration of the laser scan head compensates for internal temperature fluctuations of the laser system.

1200 x 1300 x 820

(door width 1100mm)

| Laser Type: Yb: Fiber Laser |

| Cooling: Air |

| CW-Output: 10 – 50 watt |

| Pulse Repetition Frequency: 20 to 500 kHz |

| Power Requirements: 230V / 50Hz / 16A |

| Power input approx: 0.5 – 1kW |

| Max ambient temperature: 35/50ºC |

| Laser Type: Nd: YAG-Laser (diode pumped, disc) |

| Cooling: Air |

| CW-Output: 8/16 Watt |

| Pulse Repetition Frequency: 5 – 50 kHz |

| Power Requirements: 230V / 50Hz / 16A |

| Power input approx: 1kW |

| Max ambient temperature: 35/50ºC |

| Laser Type: CO2-Laser (sealed) |

| Cooling: Air |

| CW-Output: 10 – 400 Watt |

| Pulse Repetition Frequency: 0 – 20 kHz |

| Power Requirements: 230V / 50Hz / 16A |

| Power input approx: 0.7 – 8kW |

| Max ambient temperature: 40/50ºC |

- Laser marking and engraving, on surface or circumference

- Intelligent segmentation with no discernable blending

- 3D engraving and micro-engraving

- Deep engraving

- Textures

- Embossing stamps

- Pressure rollers

- Printing plates

- Sinking electrodes

- Welding and cutting applications

- Precision components

- Heavy workpieces up to 1000kg

- Palletised workpieces

- Tools and tool holders

- Cavities

| Housing Laser Protection Class 1 |

| Dimensions W/H/D (mm) 2300 x 2350 x 2600 |

| Weight approx. (kg) 1800kg |

| Max. workpiece weight 600kg |

| Working area, mm (WxHxD) 1200 x 1300 x 820 (door width 1100mm) |

| Door opening 470mm programmable + 600mm lift table |

| Working area Traverse + Field Size |

| 70 x 70mm2 (f100) 1200mm |

| 110 x 110mm2 (f160) 1130mm |

| 170 x 170mm2 (f254) 975mm |

| 230 x 230mm2 (f330) 880mm |

1200 x 1300 x 820

(door width 1100mm)

| Yb: Fiber Laser | Nd: YAG-Laser (diode pumped, disc) | CO2-Laser (sealed) | |

| Cooling | Air | Air | Air |

| CW-Output | 10 – 500 Watt | 8/16 Watt | 10 – 400 Watt |

| Pulse Repetition frequency | 20 to 500 kHz | 5 – 50 kHz | 0 to 20 kHz |

| Power requirements | 230V / 50Hz / 16A | 230V / 50kHz / 16A | 230V / 50kHz / 16A |

| Power input approx | 0.5 – 1kW | 1kW | 0.7 – 8kW |

| Max ambiet temperature | 35/50ºC | 35/50ºC | 40/50ºC |

- Laser marking and engraving, on surface or circumference

- Intelligent segmentation with no discernable blending

- 3D engraving and micro-engraving

- Deep engraving

- Textures

- Embossing stamps

- Pressure rollers

- Printing plates

- Sinking electrodes

- Welding and cutting applications

- Precision components

- Heavy workpieces up to 1000kg

- Palletised workpieces

- Tools and tool holders

- Cavities

| Housing | Laser Protection Class 1 |

| Dimensions W/H/D (mm) | 2300 x 2350 x 2600 |

| Weight approx. (kg) | 1800 |

| Max. workpiece weight | 600 |

| Working area, mm (WxHxD) | 1200 x 1300 x 820 (door width 1100mm) |

| Door opening: | 470mm programmable + 600mm lift table |

| Working area: | Traverse + Field Size |

| 70 x 70mm2 (f100) | 1200mm |

| 110 x 110mm2 (f160) | 1130mm |

| 170 x 170mm2 (f254) | 975mm |

| 230 x 230mm2 (f330) | 880mm |