ACSYS Shark

The flagship of the ACSYS line offers impressive performance and extremely high precision. It is ideal for fast marking, deep engraving, relief structure, filigree texturing or for producing 3D shapes with the highest surface quality. Precise laser sources with up to 110 Watt ensure adequate power reserves. A sturdy structure with polymer concrete ensures temperature stability and vibration damping and forms the ideal basis for the great precision of the SHARK®.

Up to 7 movable axes with linear movable columns and additional rotary swivelling axes for the galvo head or workpiece offer maximum flexibility, even for large or palletised workpieces and special components. Optional extensions including image recognition, depth control, precision packages and customer-specific special attachments leave no need unanswered and make the SHARK® an ideal tool for industrial production.

IDEAL APPLICATIONS

- Fast marking

- Deep engraving

- Relief structure

- Filigree texturing

- Producing 3D shapes

- Round parts machining

- Inlays

- Templates

- High-precision cut parts

- Tool industry

Get The ACSYS Shark Brochure

Live Adjust System®

ACSYS offers a two-camera solution for maximum precision in machining tasks. The first camera shows the entire working area. The second camera is pointed straight through the laser beam path and allows a partial high-resolution view of the workpiece that is to be machined.

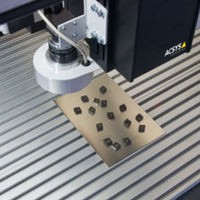

Optical Part Recognition

The optical part recognition enables the fully automated processing of non-palletized loose parts. In the example on the left, the high-resolution camera automatically recognizes the arrangement and rotational angle of the coin minting stamps.

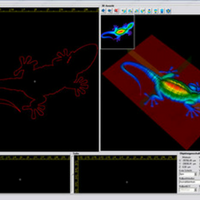

Online Depth Control

For depth engraving and 3D engraving, the material is removed down to μm-level, ensuring high-precision results. The ODC module measures the actual engraving depth contact-free and controls the exact target depth of the laser.

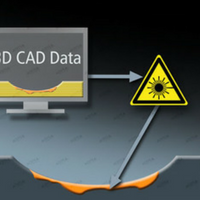

3D Assistant software module

The 3D Assistant allows a comfortable design of complex 3D engravings and micro engravings. A graphical preview simplifies the setup of the workpiece. Due to the automated readjustment of the laser focus, very deep, premium quality 3D engravings can be realized.

Dynamic Focus Control

Allows the modification of the focal point during the laser machining process. As a result, free-form surfaces can be processed without optical distortion or compromising quality. The time-consuming segmentation of the layout into different focus layers is no longer required.

Automatic Scanner Calibration

The automatic calibration of the laser scan head compensates for internal temperature fluctuations of the laser system.

- 532nm (green) IPG GLP Fiber laser 10w, 30w, 50w

- 1064nm nLight short-pulse Q-switched fiber laser 5.5w

- 1064nm IPG YLPM variable pulse (4-200ns) Fiber laser 20w

- 1064nm IPG YLP MOPA Fiber laser 20w, 30w, 50w, 100w

- 10.6µm Synrad Co2 laser 30w, 35w, 45w, 75w, 100w

- High performance galvo marking/engraving laser

- Compact floor-standing control unit

- Class 4 for ease of integration

- Industry leading laser sources including IPG and Synrad

- High speed digital beam deflection unit

- Positioning diode with Lightmark function

- Variety of lens options (70mm, 110mm, 180mm, 220mm, 300mm)

- Auto switching exhaust control (exhaust not included)

- Feature enriched software

- Start button or foot switch

- 2-year warranty

- Designed and assembled in UK – Certified CE

- Software programmable Z-axis

- Interchangeable lenses

- Rotary device small

- Rotary device large

- Tracked conveyor feed MK1 (no jig holders)

- Tracked conveyor feed MK2 (with jig holders)

- Base unit/stand

- Fume extraction unit

- Pre-configured PC

| Laser Class | 4 |

| Emergency Stop | Standard |

| Keyswitch Power on/off | Standard |

| Keyswitch maintenance (Class 4) | Standard |

| Connection external intelocks | Standard |

| Integrated safety shutter | Standard |

| CE & RoHS | Compliant |

| FDA | Approved 1310032-000 |

| Laser Wattage / Laser Source |

|

| Size (WxDxH) | W = 430 mm D = 575 mm H = 340 mm (free standing 640mm) |

| Weight | 30kg |

- 532nm (green) IPG GLP Fiber laser 10w, 30w, 50w

- 1064nm nLight short-pulse Q-switched fiber laser 5.5w

- 1064nm IPG YLPM variable pulse (4-200ns) Fiber laser 20w

- 1064nm IPG YLP MOPA Fiber laser 20w, 30w, 50w, 100w

- 10.6µm Synrad Co2 laser 30w, 35w, 45w, 75w, 100w

- High performance galvo marking/engraving laser

- Compact floor-standing control unit

- Class 4 for ease of integration

- Industry leading laser sources including IPG and Synrad

- High speed digital beam deflection unit

- Positioning diode with Lightmark function

- Variety of lens options (70mm, 110mm, 180mm, 220mm, 300mm)

- Auto switching exhaust control (exhaust not included)

- Feature enriched software

- Start button or foot switch

- 2-year warranty

- Designed and assembled in UK – Certified CE

- Software programmable Z-axis

- Interchangeable lenses

- Rotary device small

- Rotary device large

- Tracked conveyor feed MK1 (no jig holders)

- Tracked conveyor feed MK2 (with jig holders)

- Base unit/stand

- Fume extraction unit

- Pre-configured PC