Kern FiberCELL

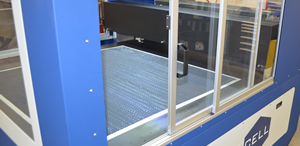

The FiberCELL is a compact sheet metal fabricating fiber laser system, capable of cutting a variety of metals such as stainless steel, mild steel, aluminum, brass and copper. A Class 1 safety enclosure allows the system to be placed in high traffic areas such as busy factory floors and university classrooms. Special polycarbonate windows are installed to ensure harmful laser wavelengths are filtered and cannot leave the enclosure.

SigmaNest® Techno™ software is included as a standard software package on each FiberCELL system. This advanced CNC laser software will maximize efficiency and machine throughput using nesting and NC functions, including common-line cutting, bridge cutting and lead–in/tab generation.

The FiberCELL uses Kern’s next generation HyperDual motion system, allowing users to take full advantage of the system’s powerful laser source.

STANDARD FEATURES

- Capacitive Height Follower

- Closed Loop Water Chiller

- Exhaust Blower and Hose Kit

- HyperDual Servo Motion Package

- LaserMech FiberMini® ST Beam Delivery

- High Performance Computer & LCD Monitor

- KCAM Laser Software

- Copper Slat Cutting Table

- Onsite Installation & Training

GET THE KERN FIBERCELL BROCHURE

Beam Delivery

Software & Hardware

HyperDual Motion

Front/Side Access

Safety Enclosure

Programmable Gas

- 500 watts

- 1,000 watts

- 1,500 watts

- Capacitive Height Follower

- Closed Loop Water Chiller

- Exhaust Blower and Hose Kit

- HyperDual Servo Motion Package

- LaserMech FiberMini® ST Beam Delivery

- High Performance Computer & LCD Monitor

- KCAM Laser Software

- Copper Slat Cutting Table

- Onsite Installation & Training

- K-Vision Camera Registration

- SigmaNest® Techno™ Software

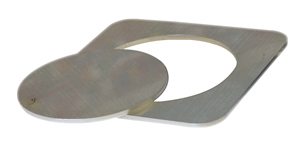

- Rotary Device

- Fume Extraction Unit

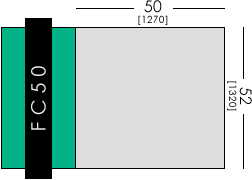

| Engraving Area | 52″ x 50″ (1320mm x 1270mm) |

| Laser Wattage | 500 watts, 1,000 watts and 1,500 watts |

| Laser Source | Fiber Laser |

| Size (WxDxH) | 74″ x 84″ x 78″ (1880mm x 2134mm x 1981mm) |

| Weight | 3700 lbs. (1678 kg) |

| Positioning Accuracy | +/- .005/300mm |

| Repeatability | +/- .013/300mm |

| Straightness | +/- .005/300mm |

| Air Assist Nozzle | Yes |

| Max Cutting Speed | 508mm/sec |

| Max Engraving Speed | 3810mm/sec |

| Vacuum Table | Yes |

| Z Clearance | 76.2mm |

| Options Available | K-Vision Camera and Pipe Rotary |

- 500 watts

- 1,000 watts

- 1,500 watts

- Capacitive Height Follower

- Closed Loop Water Chiller

- Exhaust Blower and Hose Kit

- HyperDual Servo Motion Package

- LaserMech FiberMini® ST Beam Delivery

- High Performance Computer & LCD Monitor

- KCAM Laser Software

- Copper Slat Cutting Table

- Onsite Installation & Training

- SigmaNest® Techno™ Software

- K-Vision Camera Registration

- Rotary Device

- Fume Extraction Unit

| Engraving Area | 52″ x 50″ (1320mm x 1270mm) |

| Laser Wattage | 500 watts, 1,000 watts and 1,500 watts |

| Laser Source | Fiber Laser |

| Size (WxDxH) | 74″ x 84″ x 78″ (1880mm x 2134mm x 1981mm) |

| Weight | 3700 lbs. (1678 kg) |

| Positioning Accuracy | +/- .005/300mm |

| Repeatability | +/- .013/300mm |

| Straightness | +/- .005/300mm |

| Air Assist Nozzle | Yes |

| Max Cutting Speed | 508mm/sec |

| Max Engraving Speed | 3810mm/sec |

| Vacuum Table | Yes |

| Z Clearance | 76.2mm |

| Options Available | K-Vision Camera and Pipe Rotary |