LASER CUT & ENGRAVED

MIX MEDIA GIFT

MATERIALS NEEDED

- 1mm (18 ga) mild steel

- 6mm (1/4″) acrylic (clear and black)

- 0.5mm (.020″) brushed brass (used here is from Rowmark)

- Brass acorn nuts, washers, and bolts

- Blackening chemical

- Laser engraver able to cut milt steel (Kern 400W HSE laser system)

- Graphic design software (we run CorelDraw classes throughout the year)

Click on the the finished product to zoom (Images courtesy Kern Laser and SBC Laser)

STEP 1: SET PARAMATERS

- 1mm Mild Steel

Speed: 2″/sec

Power: 90%

Frequency: 600Hz

Assist Gas: Oxygen (100psi) - Acrylic Etching

Speed: 80″/sec

Power: 25%

DPI: 300

Assist Gas: Compressed Air (20psi) - Acrylic Cutting:

Speed: .5″/sec

Power: 30%

Assist Gas: Compressed Air (5psi

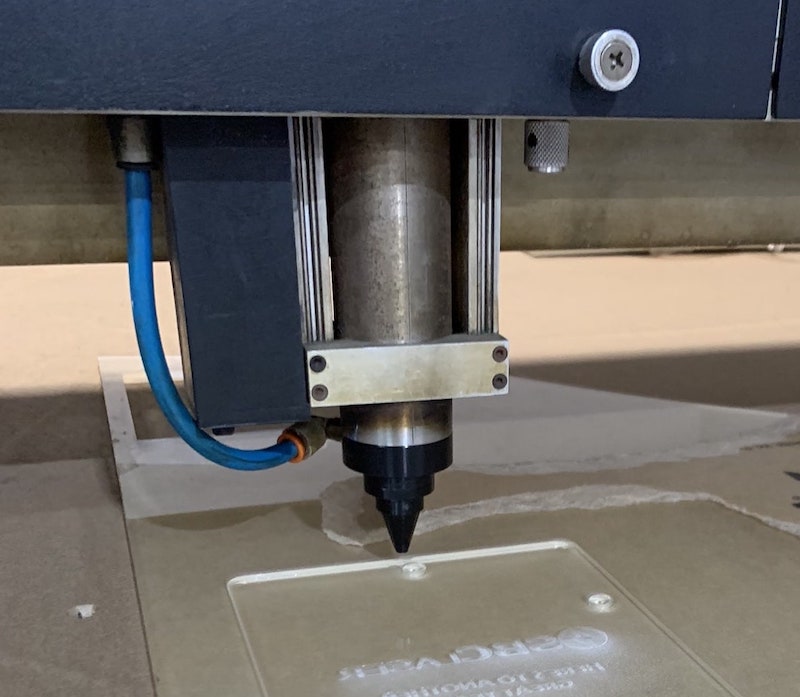

STEP 2: SET UP GLASS BOX

When cutting metal, laser focus is an important aspect. As the mild steel is cut, it heats up and tends to move around. If using a Kern (like we did for this project), the automatic height follower maintains a consistent focus point over the entire sheet.

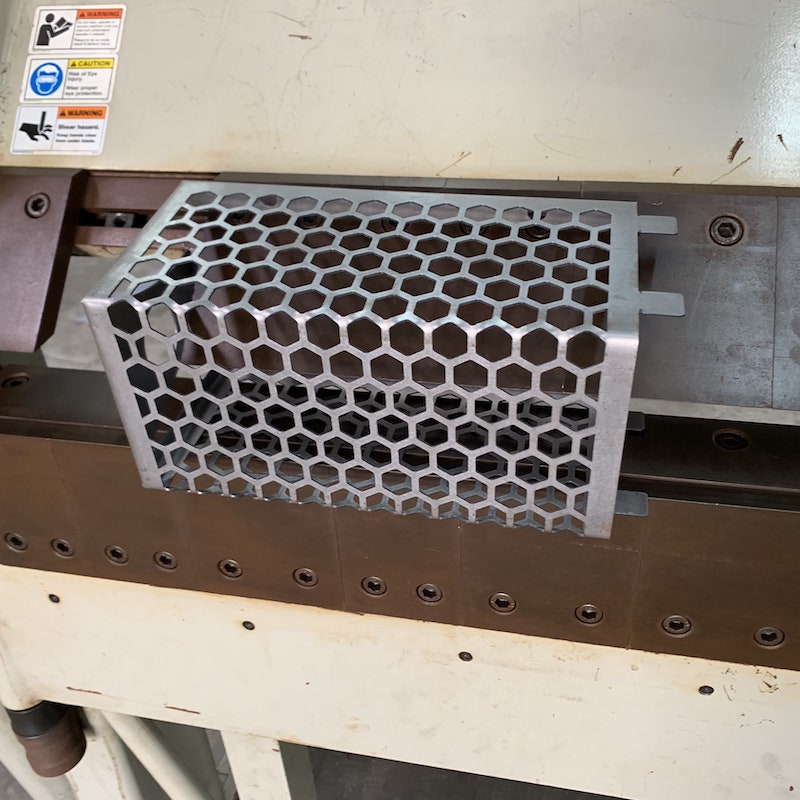

STEP 3: FORM METAL

This custom cage and base are bent using a folding table. No welding was required.

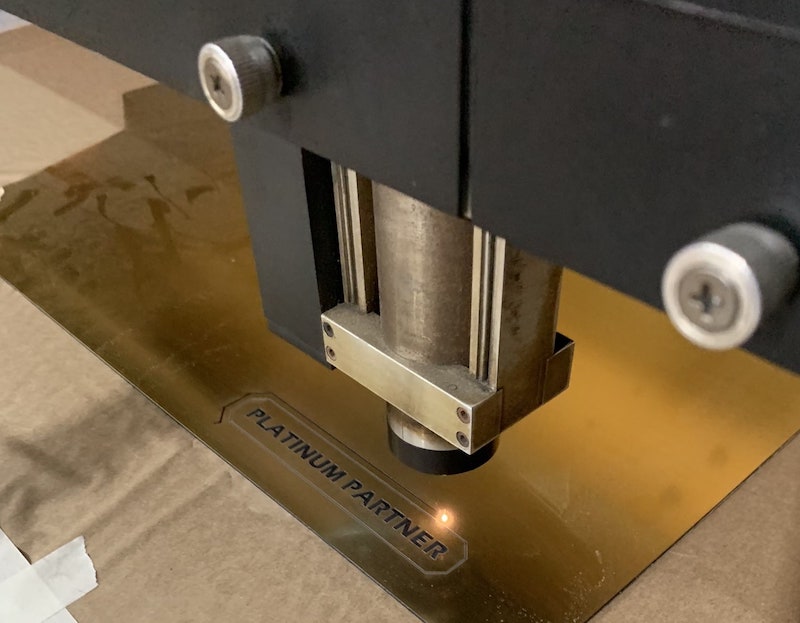

STEP 4: CUT & ENGRAVE ACRYLIC

Lasers are popular tools when processing acrylic.

.

STEP 5: BLACKEN STEEL

A chemical process used applied to the steel, giving it a blackened look.

.

STEP 6: ASSEMBLE

The only fasteners used on this project are decorative brass acorn cap nuts.