The University of Melbourne Expands Laser Capabilities With Alfex CNC Australia For Students to Achieve Real World Applications.

The Melbourne School of Design at University of Melbourne initiative for 2018 was to expose students to relative industry machinery and processes that they would potentially use as designers and architects after graduation. A complete laser cutting and engraving system that was safe to use in the classroom as well as flexible enough to have all the features needed inside a workshop meant the LaserCELL by Kern Laser Systems was the perfect solution.

Australia’s leading university, The University of Melbourne, is known to help graduates become thoughtful and skilled professionals. With their distinctive curriculum, the Melbourne Model, The University of Melbourne continues to seek ways to give students a wider understanding of the world beyond their degree.

Dr.

“We find that once the students have access to the machinery and its capabilities, it opens up their creativity”

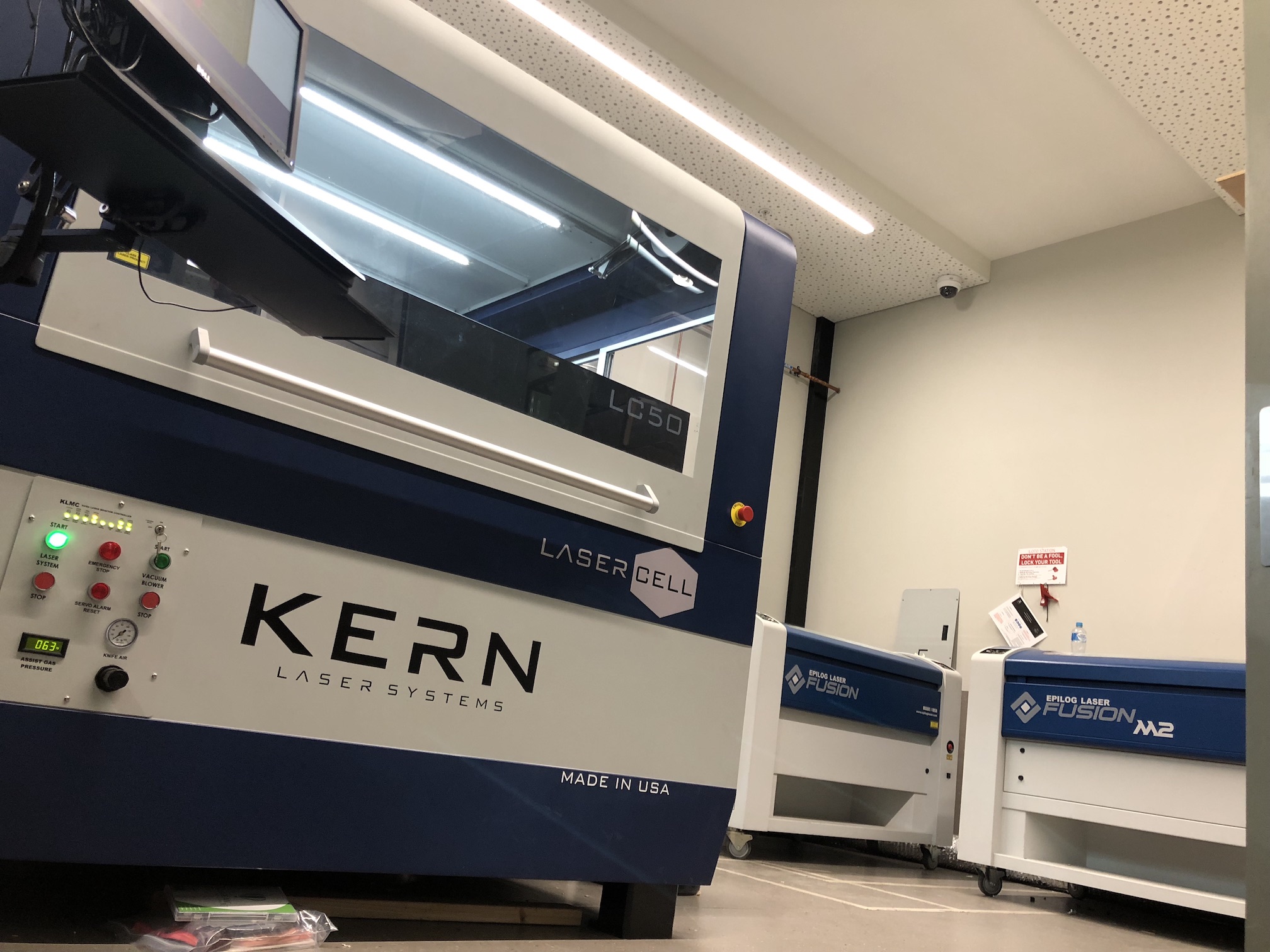

More laser systems, more capabilities: Kern LaserCELL together with Epilog Fusion Lasers all from Alfex CNC Australia.

The University required a laser system that was capable of cutting stainless steel,

Issues with equipment usually stem from incorrect setup, which can lead to students to lack confidence in using the machinery again. “Having the Kern engineers come in from the USA and the local Alfex CNC engineers to set up the LaserCELL really boosted our confidence in knowing that the LaserCELL would be set up properly from the get-go and we would have expert support here in Melbourne.”

“Another reason why we went with the Kern LaserCELL over other systems, is that it will still process all the other materials our students use. We needed the variety of materials as well as metals.”

“The LaserCELL is perfect for educational settings due to the blend of performance and safety. The fully enclosed (Class 1) design is devised for high traffic areas such as University workshops and classrooms where safety is of the utmost importance”, said Christian Buhagiar, Business Development Manager of Alfex CNC Australia. Now that students have access to industrial machinery, Dr. Johnston says their first project with the LaserCELL is an augmented reality workshop.

The workshop will see students use the LaserCELL to cut flat sheets of metal to create hologram instructions. The LaserCELL will also be heavily used for Furniture Design projects. The LaserCELL is Kern’s fastest and most productive machine to date and is compatible with Pipe Rotary, K-Vision Camera Registration and Metal Cutting options.“Our goal was to get students more access to machinery in the industry. With the Kern LaserCELL we’re confident that we’ll see new and innovative ideas in the classroom” said Dr. Johnston.

“Our goal was to get students more access to machinery in the industry. With the Kern LaserCELL we’re confident that we’ll see new and innovative ideas in the classroom”

“We’re very proud of the relationship that Alfex and the team at Melbourne University have built over the years. It’s always a pleasure working with Jas, Sean and the guys, and we’re really excited to see them put the Kern LaserCELL to good work. There will no doubt be many impressive projects come from this new installation”, said Buhagiar.

For more information on the Kern LaserCELL and how you can use it in your

A sample made with the new LaserCELL – this deep engraving was achieved in one pass!